Inspection Services

PFL’s Inspection Services focuses on conventional and specialized Inspection and Non Destructive Testing (NDT) coupled with efficient management and cost effective implementations. We provide a complete integrated service to a variety of industries and Clients. At PFL we utilize state-of-the-art equipment and highly trained technicians.

All our technicians are IRATA certified Rope Access Technicians all with a multi-disciplined approach and with a vast selection of disciplines. This allows for multiple scopes to be carried out single source.

Our Inspection Services Include:

- General Inspection;

- Risk Based Inspection

- Corrosion Monitoring and Mapping

- Coating Inspection

- Welding & Coating Inspection

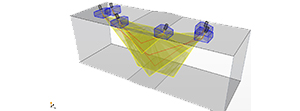

- Remote Aerial Inspection

- Close Visual Inspection

At PFL we understand the importance of NDT services to our clients. Not only can our clients improve Use Asset reliability, reduce operational and maintenance costs, enhance safety and extend plant life, they can monitor and improve their operations across the board.

These findings are documented with photographic support and we subsequently provide corrective recommendations for their rectification.

Most importantly, items that are considered high risk are repaired by the technicians, after all, most of these are inaccessible without Rope Access.