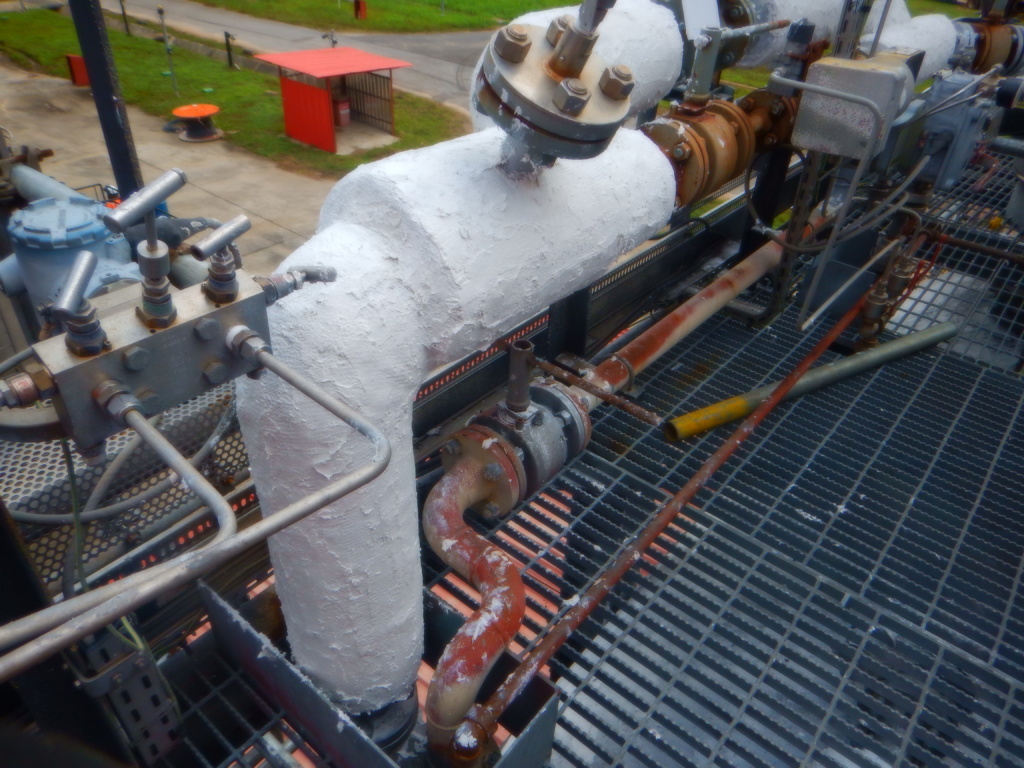

Corrosion Under Insulation remains a continuous challenge in the Oil & Gas industry due to accessibility and visibility. It decreases asset productivity, endangers the environment and puts workers at risk.

As an Asset Integrity Management (AIM) service provider therefore, it is essential in choosing the correct material for the job and ensuring the best and most professional surface preparation is done.

PFL Engineering offers its expertise in Insulation services using vast range of materials and techniques which include Cellular glass, Mineral wool, Polyurethane [PUR], Polyisocyanurate [PIR] and more.

When we are given the opportunity to select insulation materials, we choose the best applicable materials and methods that have the most to offer when providing Thermal Insulation, Acoustic Insulation, Fire Protection, Corrosion Control and Heat Tracing. Meeting our client’s ‘mission critical’ facility AIM requirements at best cost while ensuring the safety of people and environment is paramount to us at PFL Engineering Services.

Being an AIM services company, we can give the required access to the work area via Scaffolding, Rope Access and Tensioned Netting. We also ensure the correct surface preparation and specialist coating systems are correctly applied, to ensure the maximum lifespan of the unit being protected.