PFL Engineering Services Limited is proud to announce its ISO 9001:2015 certification for quality following a comprehensive audit, Read more

Increasing Asset Lifetime, Improved Productivity, And Protecting Workers & the Environment

From cryogenic cold to super heated steam temperatures, there are various insulation materials to suit your need in the Oil & Gas, Marine, Petrochemical and Marine Industry. PFL Engineering services can boast of qualified and experienced Insulation application team that is vast with the usage of Cellular glass, Mineral wool, Polyurethane [PUR] and Polyisocyanurate [PIR] insulation materials.

When given the opportunity to select insulation materials, PFL Engineering chooses the insulation with the most to offer when dealing with the demands of an end user’s ‘mission critical’ facilities. As an AIM services company, we can provide the required access and the correct surface preparation of surfaces prior to the application of insulation materials according to client specification.

PFL Engineering’s most recent project experience was the insulation protection of Reboilers, piping and stripping columns at Obite Gas plant in Rivers State.

SCENARIO: Insulation installed on some of the high temperature vessels for the TEG Unit and interconnected piping is currently damaged. The client wishes to use the opportunity of a plant shutdown to carry out anti corrosion works on these high temperature vessels as well as replace the damaged insulation on interconnected piping.

BEFORE PICTURES

Figure 1 – Damaged Insulation on Still Column

Figure 2 – Damaged insulation on TEG Unit

SOLUTION: The preferred choice was Pre-Fabricated Foam Glass [Cellular Glass] product. The project execution was carefully planned for 25 days amidst the rainy conditions at site. Crews were grouped to work day and night as approved by the client. Scaffolding, Blasting and Painting activities were carried out before final application of the insulation material.

AFTER PICTURES

Figure 3 – New Insulation on TEG Unit

Figure 4 – New Insulation on Still Column

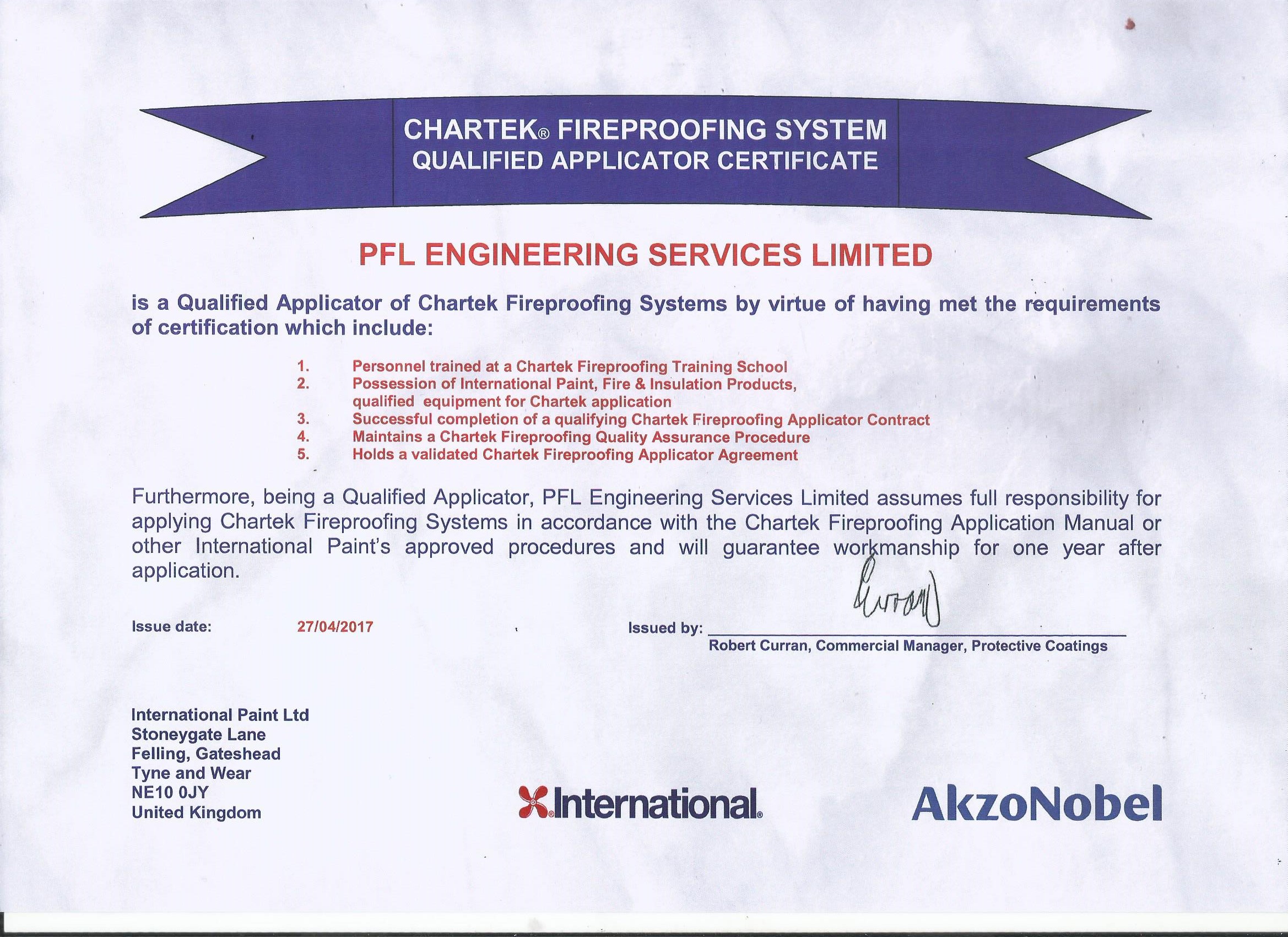

PFL ENGINEERING SERVICES RECEIVES CHARTEK FIREPROOFING APPLICATOR CERTIFICATE

PFL Engineering Services Limited receives the Chartek Fireproofing System’s Qualified Applicator Read more

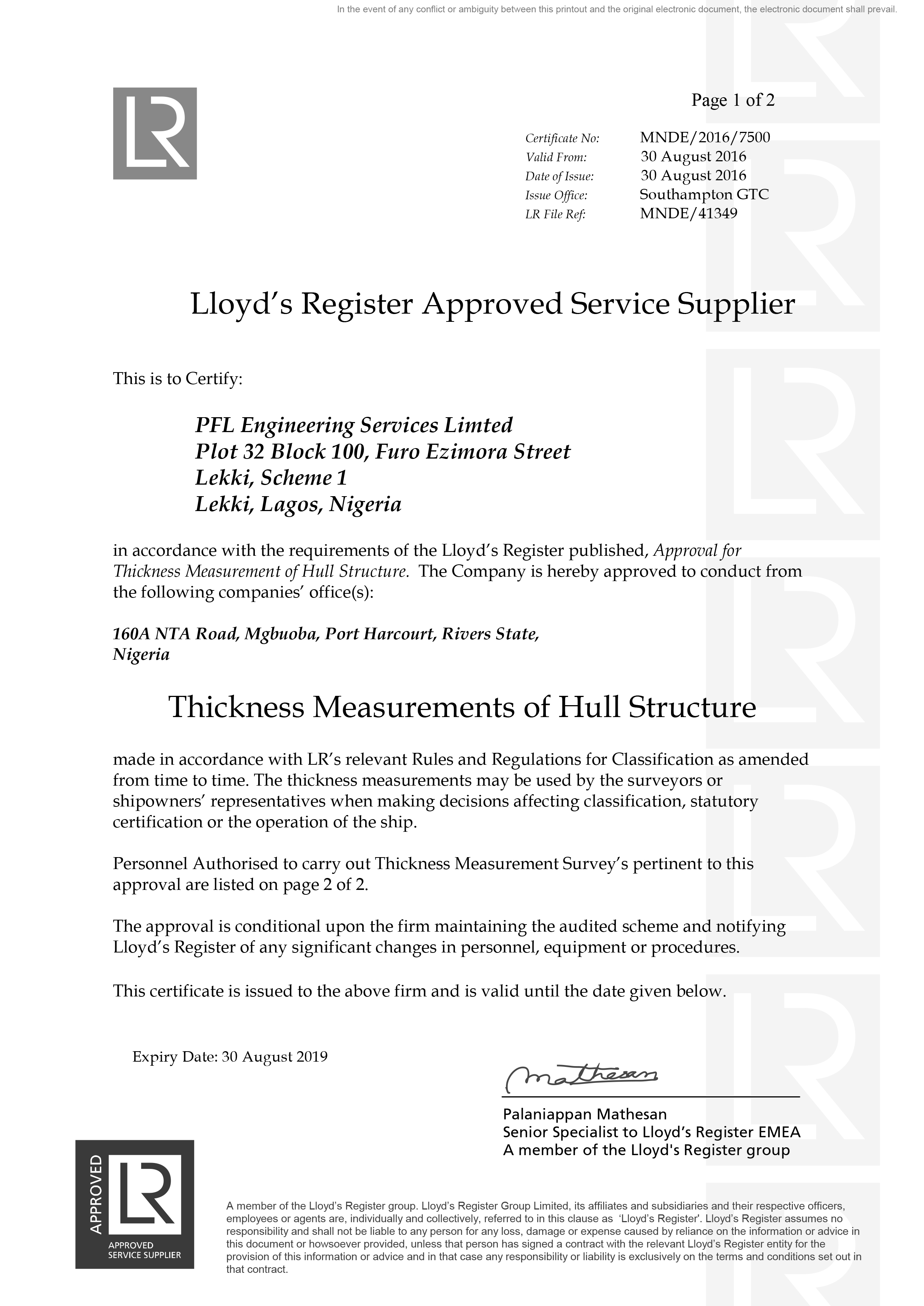

PFL RECEIVES LLOYD’S REGISTER APPROVED SERVICE SUPPLIER

PFL Engineering Services receives Lloyd’s Register Approved Service Supplier

PROUDLY NIGERIAN AND EXPANDING INTO NEW AFRICAN MARKETS

How did PFL Engineering Services Limited start and what was the motivation behind it?

The company started as a normal Nigerian company established by a team of experienced, committed and dedicated Nigerians that saw the need to offer quality service to the oil & gas community. The main motivation was to set up a business that will be a platform for Nigerians to grow in the oil & gas industry and provide unrivaled services that will show case the physical and technical strength of an average Nigerian.

What services are proving the most popular among your clients and why do you think this is so?

While we were planning the re-engineering of the company, we wanted to diversify to areas that will remain active for a long time not minding the cost of crude and realized that maintenance will always be key in the industry because IOC’s might reduce or cancel Greenfield Projects but will always need to maintain their Brownfield Assets so as to remain in business. So we re-organized and developed ourselves in the Inspection and Maintenance business which is key for any Asset owner that still wants to maintain high level production.

Do you feel there is a growing awareness of the importance of safety in the Nigerian oil and gas industry?

Yes, there is a lot of emphasis now by all the IOC’s operating here in Nigeria and it is a good thing as we want our people to be safe and well. There are now minimum standards every company must attain to be able to execute projects in the industry. On our part, we take safety very seriously and have gone ahead to invest and develop our operating system by securing ISO 18001:2007 from Bureau Veritas UK. This proves that our laid down processes and procedures on safety conforms with the highest internationally recognized safety standard in the world today.

How important are your services in encouraging operators to meet local content requirements in Nigeria?

We are a 100% indigenous company and we feel very strongly about local content and encourage it as much as we can. We have ensured we have full International certifications for our company operations and management. We are fully certified in ISO 9001: 2008, 14001:2007 and 18001:2004 all from Bureau Veritas UK giving us a fully compliant Integrated Management System (IMS). We have developed our system in such a way that we will be able to compete with any company anywhere in the world. We have made ourselves attractive so as to ensure IOC’s do not have to bother about sourcing for international companies to render our scope of service here in Nigeria and the sub-region.

Chief Executive, PFL Engineering Services Limited, Preye Berezi

What are the common challenges PFL Engineering faces in this industry and how do you overcome them?

One of the challenges we face on a daily basis is the price war that has erupted since the cut back in oil price, everyone is now cutting costs as the IOC’s are trying to make their operations leaner. You have to be really careful as you do not want cost cutting to impinge on your quality and safety during operations. We are lucky because we invested in the essentials of our business (personnel, certification and equipment’s) at the right time so we are able to be very flexible with our prices.

Another area that is still a challenge is our tendering process in Nigeria. Apart from the fact that it takes too long to get a project rolling, IOC’s and especially Government regulators have to put in more effort and be more upright in the pre-qualification of companies for projects. We still have too many unqualified companies bidding and qualifying for contracts that they have no technical strength on because they have friends in high places. This will not encourage the need for Nigerian companies to develop their operating systems.

Recently you received the Lloyds Register approved service supplier certification. How important are certifications to the Oil and Gas industry in Nigeria?

We have not only got our Lloyds, we also have ABS and we are about securing DNV. These are the type of International certifications which make you stand out in the industry and we aim to be the best.

Certifications are important because they show the strength you have technically. It’s like qualifications you gather from going to school. If our company was a student, we would have been talking about been an Associate Professor with the sort and class of certifications we have been able to secure over the years after going through rigorous audits by international bodies and agencies.

What plans does PFL Engineering Services have for the future?

We look into the future with so much confidence and enthusiasm, like I said earlier, we invested on the essentials of the business a while ago and are now uniquely positioned to offer first class service in our chosen fields.

Furthermore, we are presently expanding our Operations/Training Base in Port Harcourt to offer Valve Maintenance Services, so we are setting up a Valve maintenance workshop. This is important because we represent one of the biggest manufacturers of specialist valves in the world IMI CCI of the USA and we are also Channel Partners to Draeger Safety another household name in the world of safety and firefighting. To service our safety clients we are also setting up an ultra-modern Safety Centre in Port Harcourt where we will be able to calibrate safety equipment’s like Gas Detectors, BA sets, Diving Sets e.t.c. We have so far achieved 70% completion and plan to commission these two projects in December this year.

We have invested heavily in equipment and construction to ensure we can compete with the best in the business. We are looking at new innovations and we have recently added Drone Technology to our profile. We believe to be the best you must keep up with technological development.

We have recently exported our business beyond the shores of Nigeria by establishing in Ghana. We plan to work with reasonable and committed Ghanaians and set up a training center in Takoradi, Ghana, early next year.

PFL ENGINEERING SERVICES LIMITED MOVES INTO NEW OFFICE, EYES FUTURE EXPANSION

These are exciting times at PFL Engineering Services Limited. As the CEO explained, “We have settled into our new office and looking forward to the future”.

PFL ENGINEERING SERVICES LIMITED RECEIVES ISO 9001:2015 CERTIFICATION

PFL Engineering Services Limited is proud to announce its ISO 9001:2015 certification for quality following a comprehensive audit, Read more